About My Work

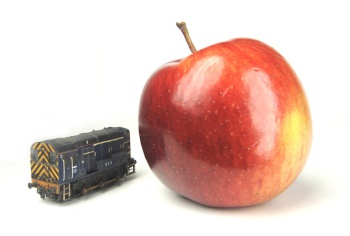

Every Mercig model is a unique one off finely crafted piece of work. A huge amount of time goes into every model and in this section I will try to show just some of the work that goes into the making of a Mercig model. All the models shown on this website are N Gauge (2mm:1ft).

Most of the models on this page can be enlarged by clicking on the images. When looking at the models please note that you are looking at an object that is usually just over 2cm in height with the largest locomotives only about 13cm in length.

Super Detailing

Virtually all the models featured on this website have had some degree of detailing work done to them. The detailing can be anything from adding snowploughs, nameplates, handrails and headlights to more complex conversions. As the quality of ready to run models increases the need for detailing is steadily coming down as can be seen with the new Farish class 37 that needs little detail work as opposed to the older class 50 that needs large amounts of detail work in order to bring it up to an acceptable standard.

Most of the locos that are on the website will also have super detailed buffer beams, which include vacuum pipes and screw couplings. Buffer beam detail is usually only applied to one end so as to allow the normal n gauge coupling to be used at the other end. All nameplates, depot plaques, silver BR logos and air horns are made from etched metal.

Class 47 showing detailed buffer beam and etched nose cables, even with a prototypical loop around the catch. On the nose you can also see the original plastic moulded hand rails replaced with wire versions including the pommels. Windows have also been worked on to show where the wiper blades keep the windows clean.

Class 47 showing detailed buffer beam and etched nose cables, even with a prototypical loop around the catch. On the nose you can also see the original plastic moulded hand rails replaced with wire versions including the pommels. Windows have also been worked on to show where the wiper blades keep the windows clean.

Class 24 which shows super detailed buffer beam with headcode discs at the correct

thickness as well as the nose resprayed to represent full yellow ends.

Class 24 which shows super detailed buffer beam with headcode discs at the correct

thickness as well as the nose resprayed to represent full yellow ends.

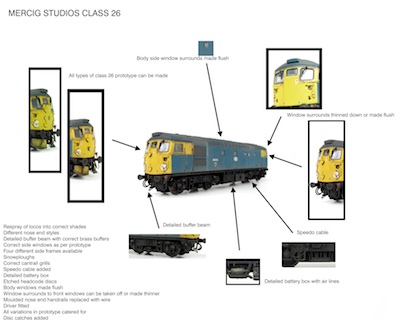

Class 26 information sheet that shows just some of the various detailing that can be carried out to the model.

Class 26 information sheet that shows just some of the various detailing that can be carried out to the model.

Fading

Fading paint on the models is achieved by multiple layers of base coat as well as other techniques used on the top coat. This can be most visibly noticed on the body and nose ends where typically 3-4 different shades are used just for the base in order to achieve a prototypical appearance and to give the model a depth of field.

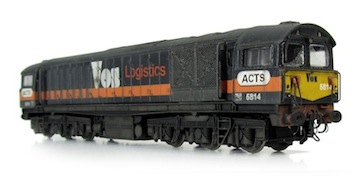

Some extreme fading can be seen on this class 47 with added special effects of paint peeling which matches prototype photos of the loco whilst in service for NSE.

Some extreme fading can be seen on this class 47 with added special effects of paint peeling which matches prototype photos of the loco whilst in service for NSE.

Bogies and Underframe

A large amount of work goes into the under frame to make it look as realistic as possible. The model is always taken apart so as no paint is allowed to get into any of the mechanical parts of the locomotive, with the actual bogies worked on so that when you look through the frames there is no unsightly black plastic. Numerous techniques are used on the frames and battery box to give the impression of brake dust, oil and grime build up.

Various bogie frames that show the different levels of shades produced by brake dust, oil and grime. Final photo shows the textured build up dirt on a class 42 wheel rim.

Various bogie frames that show the different levels of shades produced by brake dust, oil and grime. Final photo shows the textured build up dirt on a class 42 wheel rim.

Weathering

The weathering is a sum total of all the above mentioned methods. Added to this you will see many other techniques used on the models such as streaks, exhaust fumes and grease on the buffers which make the models look as close to reality as possible.

All the models are sealed with multiple layers of varnish so that the models should always maintain their look. Different types of varnish are used from matt through to gloss in order to get a prototypical appearance. This is something that is hard to see from photos but there is a variation in tone on the majority of models representing such things as gloss paint breaking through dirt and greasy wheel sets.

A 4MT heavily weathered to represent steams end of days. Other added details include a loco crew, renumbered, detailed buffer beam, etched depot and work plates and real coal added to tender.

A 4MT heavily weathered to represent steams end of days. Other added details include a loco crew, renumbered, detailed buffer beam, etched depot and work plates and real coal added to tender.

... this. Note the frost grills and bogie modification that reduces the gap between the body and the top of the bogies.

... this. Note the frost grills and bogie modification that reduces the gap between the body and the top of the bogies.

Renumbering and Re-livery

Virtually all the locos on this site have been renumbered from their original. Specially commissioned dry transfers have been used on the vast majority of models which avoids the rather ugly edges that you tend to see with water-slide transfers.

Re-sprays

Models can be resprayed from their original livery into any livery the customer wants. A great deal of time and effort goes into creating a perfect finish.

Conversions

Locos can be converted into a wide range of different sub classes and styles.

Photo above shows the different levels of conversion that can be taken out on a Farish class 24 from respraying the nose end yellow right through to a conversion to a 25/0.

Photo above shows the different levels of conversion that can be taken out on a Farish class 24 from respraying the nose end yellow right through to a conversion to a 25/0.

Class 45 showing a conversion to a plated-over headcode version. The loco has also had a full respray into BR blue as well as slimmed down bogies.

Class 45 showing a conversion to a plated-over headcode version. The loco has also had a full respray into BR blue as well as slimmed down bogies.

Special Effects

Class 26 weathered to represent a scrapline loco in its final days with lots of special effects including broken/boarded-over windows, paint bubbling/peeling, rust patches and heavily-faded paint work.

Class 26 weathered to represent a scrapline loco in its final days with lots of special effects including broken/boarded-over windows, paint bubbling/peeling, rust patches and heavily-faded paint work.

Presentation Box

All Mercig Studios locos come in a presentation box. The box features a de-embossed lid and protective outer sleeve with a signed certificate of authenticity. You will also find that all locomotives are signed underneath the body and on the under-frame.